Waste gaskets & oil-seals shredder

Product Details:

Waste gaskets & oil-seals shredder Price And Quantity

- 1 unit

- 121000.00 - 290000.00 INR

Waste gaskets & oil-seals shredder Trade Information

- Mumbai

- Days after Acceptance (DA) Cash on Delivery (COD) Letter of Credit (L/C) Cash Against Delivery (CAD) Telegraphic Transfer (T/T) Cash in Advance (CID) Cheque

- 50 unit Per Month

- 3 Week

- Standard export wooden packaging or as per customer's request.

- Australia North America Eastern Europe Western Europe Africa Central America Middle East South America Asia

- All India

- Company Certifications:- MSME (GoI) Udyog Aadhar No.:- MH33B0009887 Import Exporter code:- 0306091216 MSME (GoI) Entrepreneurs Memorandum No.:- 27-021-12-03228-Part II

Product Description

Gaskets and oil-seals are widely used for interface sealing purpose in various product manufacturing and other industries. These products have a lifespan after which they are discarded. Such waste gaskets and rubber seals are shredded before further processing.

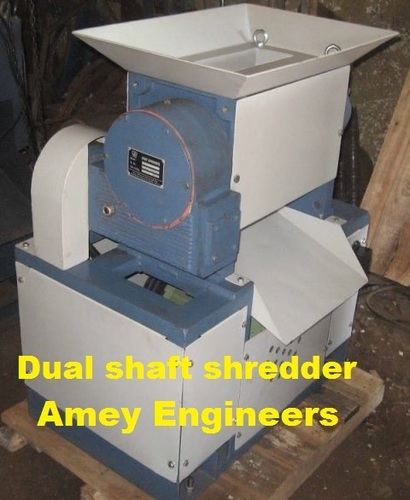

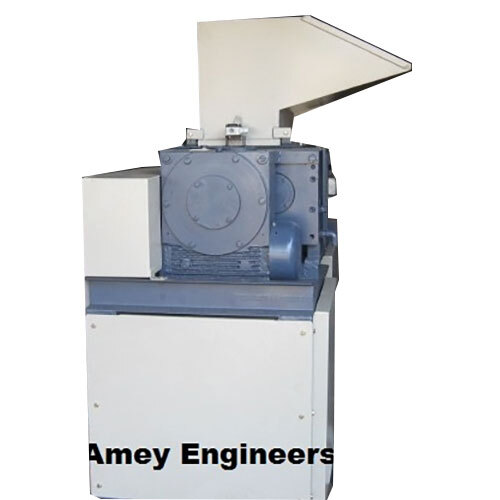

Amey Engineers' PS and PS H range of medium to heavy duty dual shaft shredders are optimally suited for shredding all such types of rubber gaskets, oil-seals and also small scrap molded rubber wastes. PS and PS H series of shredders use standard 3 phase IP rated electric motors ranging from 2 hp to 12.5 hp. Drive shafts are of alloy steel and duly toughened. Cutters are of alloy steel case hardened type with diameters of 120 to 170 mm across the PS and PS H range. Cutters are offered in various tooth configurations. Linear cutting speed is 13 m/min for PS series & 18 m/min for PS H series. Low speed and high torque principle of working ensures effective shredding and smooth operation. Throughput obtained is between 30 to 200 kg/hr and depends on the shredder model configuration and rate of feed. Standard feed widths across the PS and PS H shredder series are from 310 mm to 610 mm.

Other features include base heavy construction, low maintenance, low noise operation, easy installation. Safety features include emergency stop, overload protection, operator safe design.

Standard models in PS and PS H series of shredders include: PS 300, PS 400, PS 300 H, PS 400 H, PS 600 H.

For still higher throughput requirements, SM and SM HD series of heavy duty dual and four shaft shredders are also available.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese